WMH Transmissions Ensures Global Manufacturer of Disposable Wipes Continues Production

WMH Transmissions Ensures Global Manufacturer of Disposable Wipes Continues Production

The Situation

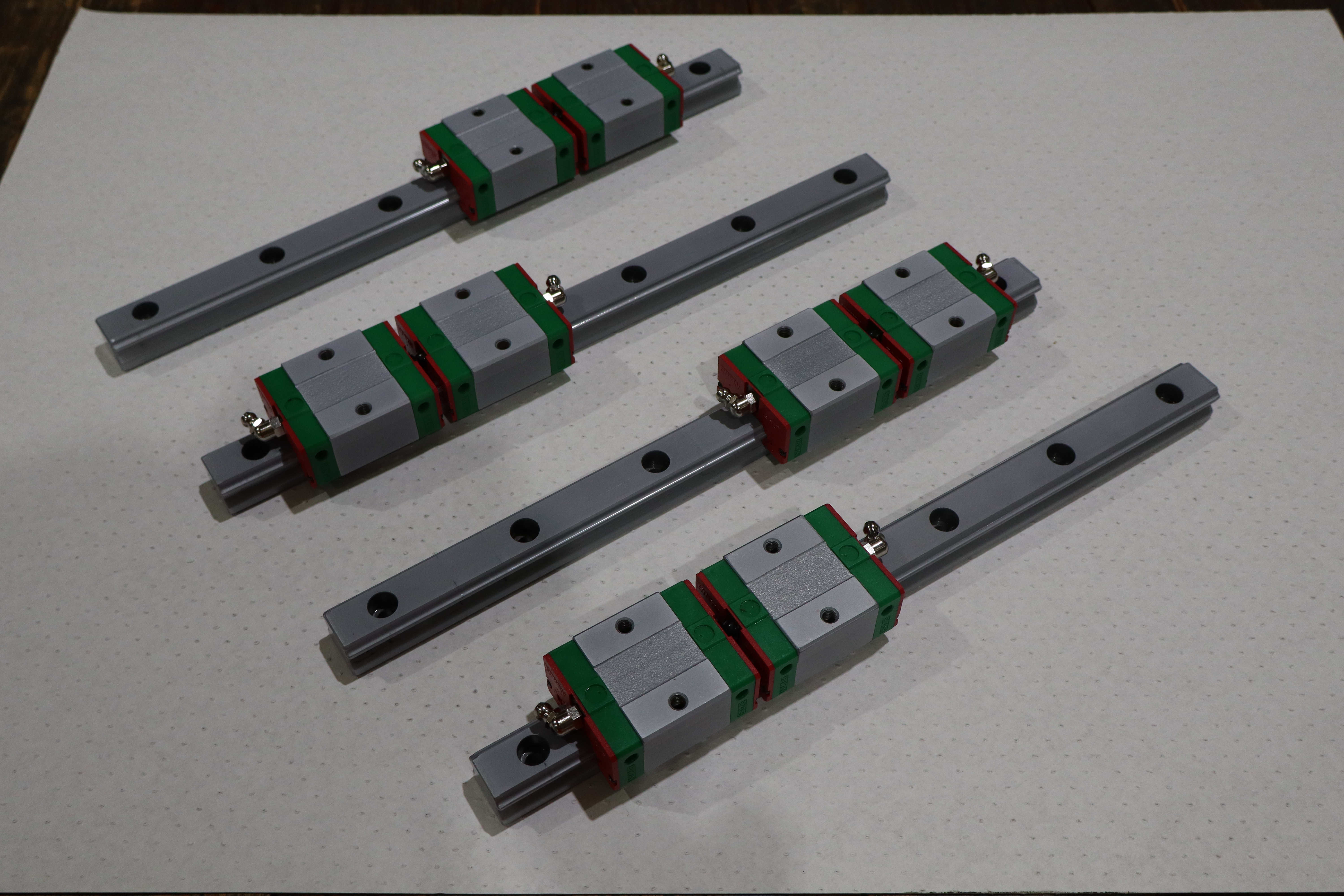

A global manufacturer of disposable wipes approached WMH Transmissions in mid-February 2024. After the critical stock of replacement parts had depleted, four linear guide block and rail assemblies were required to ensure that operations were able to continue. These needed to be armoloy coated to ensure strict compliance with food-grade safety regulations. This ensures that any metallic properties do not compromise the quality and safety of the operations.

The Solution

We intially offered two solutions - the choice of stainless steel or armoloy coating on the required parts. Through discussion with the customer, it was decided that the armoloy coating was selected for both cost-effectiveness and availability.

After the in-stores team picked the required parts to be stripped, the linear guide block and rail assemblies were then sent out to be coated with this unique metallic coating. The chromium finish offers numerous benefits for streamlining operations through heat-resistant and anti-corrosive measures.

After receiving the coated blocks, they were re-balled with stainless steel balls to avoid corrosion, and tested on a rail to ensure it fits within the limit of the pre-load.

The Result

Following the supply of four HIWIN linear guide block and rail assemblies to the facility within a 10-day leadtime, the customer was able to continue operations, saving maintenance costs and reducing downtime.

By providing services with added value, like armoloy coating, you can be confident that we can support your project, whether this requires a simple off-the-shelf component or a more complex solution.

Key Results

Added-value services

Time-saving operation achieved

Key Solution

HIWIN AEGH25SA